Thermal Spray Masking Tapes, Fabrics & Compounds

Silicone coated Fiberglass Masking Tapes for HVOF, Plasma, and Grit Blasting

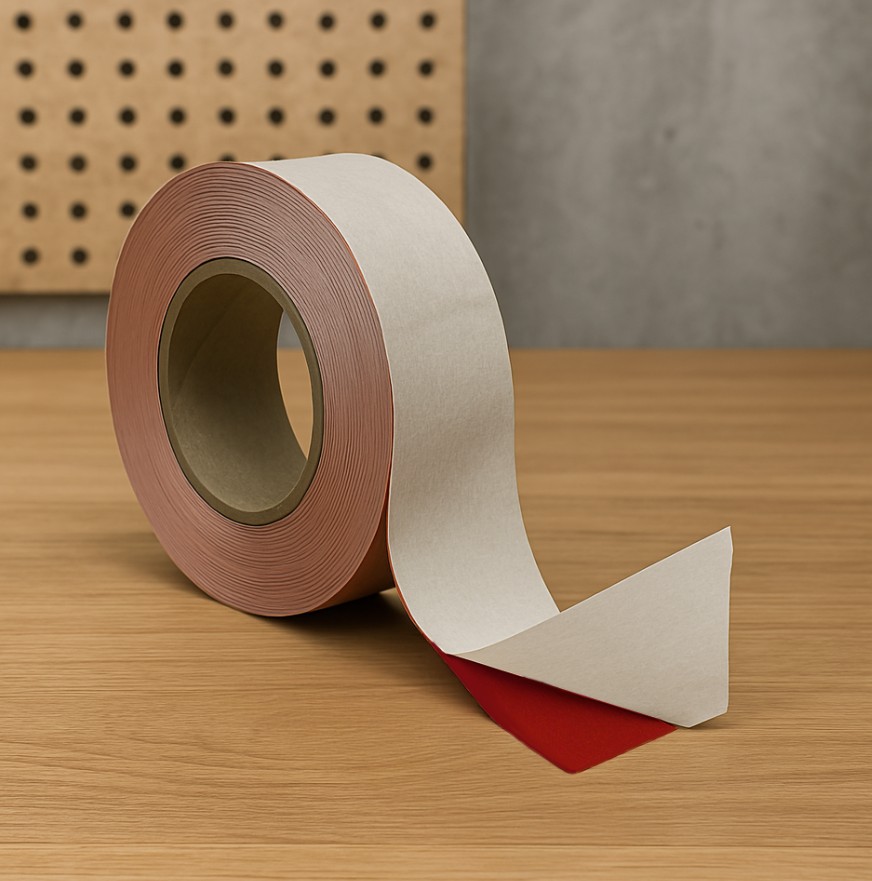

Say hello to 6525-08 RD - a breakthrough in plasma spray masking technology

Click here for more information »

Taconic manufactures high-performance thermal spray masking tapes, including silicone-coated tapes, fabrics, and compounds, engineered to protect critical surfaces during abrasive blasting, plasma spray, flame spray, electric arc, and shot peening operations. Primarily built on silicone coated fiberglass substrates, these products withstand extreme heat, pressure, and particle impact while maintaining clean release and dimensional stability.

As a U.S. manufacturer since 1961, Taconic supports customers across aerospace, automotive, energy, turbine repair, industrial coatings, and heavy-equipment manufacturing industries with reliable masking solutions that reduce downtime and improve coating precision.

Abrasive Blasting also known as grit blasting, is an important form of surface treatment required to clean part surfaces and to provide an etch to assist with the mechanical bond of thermal spray coatings to the substrate. This process involves firing abrasive particles through a nozzle using compressed air. The particles range in coarseness from fine to very coarse and can be consistant of aluminum oxide, metallic, or glass beads. Grit blasting is required prior to any thermal spray coating being applied.

Combustion Flame Spray Options

Combustion Flame Spray (also known as traditional thermal spray coating) involves using a combustible gas as a heat source to melt feedstock in the form of a powder, wire, or rod and to propel the melted droplets at the component surface. The droplets impact the surface and thus the coating is formed. Masking for flame spray coatings can be challenging as heat is a factor.

Electric Arc Spray Options

Electric Arc Spray also known as twin wire arc spray coatings, are a form of thermal spraying whereby 2 feedstock/ consumable wires are fed into the spray gun. The wires are subsequently charged and an arc is created between the two wires. The heat generated from the arc melts the feedstock wire as it is “fed” into the gun. The melted wire droplets are propelled by an air jet through the nozzle of the gun. The particles impact (splat) on the surface of the component forming the coating.

HVOF Options

Gas Fueled High Velocity Oxy Fuel coating is a form of thermal spray used to create very dense well bonded coatings onto a component surface. Typically carbide and metal powders are semi-melted and propelled at the part surfaces at high speeds (800-1500 M per second). GF-HVOF coatings are used in a variety of industries including aerospace, energy, and general manufacturing. Common applications for GF-HVOF coatings include wear resistance (carbide coatings) and corrosion resistant/bond coatings (MCrAIY)rayed aluminum or zinc, conductive coatings, and coatings for wear resistance.

Plasma Spray Options

Plasma Spray Coatings are part of the thermal spray coating family. Air plasma spray (APS) is a process used to produce high quality coatings by making use of a high energy source, very high temperatures, and inert spraying source (Argon) and high velocity particles. The result is a significantly pure coating. APS allows for the coating of some materials that would otherwise be impossible to melt such as TBC (ie. ceramic coatings).

Shot Peening Options

Shot Peeting surface treatment is a process used to produce a compressive residual stress layer and modify the mechanical properties of metals. The process involves striking the substrate surface with shot (round metallic, glass or ceramic spheres) with force. The process is intended to strengthen and relieve stress in critical metal components. The main goal is to prevent the formation of micro-cracks.

| Part Number | Substrate Thickness (inches) | Adhesive Thickness (inches) | Adhesive Type | Adhesive Strength (oz/inch) | Max Operating Temp. (°F) |

|---|---|---|---|---|---|

| Thermal Spray Tapes | |||||

| 6605-07 | 0.007 | 0.002 | Silicone | 40 | 500 |

| 6615-07 | 0.007 | 0.003 | Silicone | 50 | 500 |

| 6615-12 | 0.0122 | 0.0056 | Silicone | 45 | 500 |

| 6625-07 | 0.0065 | 0.0033 | Silicone | 70 | 500 |

| 6625-09 | 0.0085 | 0.0043 | Silicone | 50 | 500 |

| 6625-11 | 0.0105 | 0.0043 | Silicone | 50 | 500 |

| 6525-08 | 0.011 | 0.003 | Silicone | 50 | 500 |

| 6525-08 RD | 0.008 | 0.003 | Silicone | 40 | 625 |

| 6525-16 | 0.021 | 0.003 | Silicone | 20 | 500 |

| 6725-15 | 0.015 | 0.006 | Silicone | 50 | 500 |

For more information:

Contact Us »