Taconic PTFE Contact Grill Belts

High performance nonstick belts for industrial grilling

Taconic PTFE Contact Grill Belts

Product lineup overview

A1121 – Standard economy grade

A1121 is our standard, economy grade 13 mil offering. It provides excellent nonstick release, reliable performance and long service life at an attractive cost, making it a preferred choice for many contact grill applications.

A1085 – Enhanced coating for harsh environments

A1085 offers all the benefits of A1121 with a more robust nonstick coating. This 14 mil product is designed to withstand some of the harshest contact grilling environments thanks in part to its high tear strength, the best of all three products in this lineup.

A1060 – Premium high performance option

A1060 is our top of the line 12 mil product. It combines the best aspects of A1085 and A1121 while adding superior heat transfer and release properties, excellent thermal conductivity and durable anti wicking and staining characteristics for demanding production lines.

Why choose Taconic contact grill belts

Durable grill belts and dependable service are what you need. At Taconic, that is exactly what you get. With our high performance nonstick belts, you can reduce belt changeovers, improve throughput and maintain consistent quality across your grilling operations.

- Q&D driven by innovation: Our engineering staff is continuously improving existing belt materials and developing new, application specific PTFE coated fabrics that solve common issues such as sticking, wicking, staining and uneven browning found with competitive products.

- An example of this innovation is our A1060 material, developed after extensive research on competitive belts that struggled with release and wicking and staining problems. The result is an industry leading, wear and stain resistive belt material at a competitive price point.

- Quality control and testing: Each coated master roll goes through a rigorous series of tests to ensure consistent quality. We monitor tensile strength, tear strength, dielectric strength and other key properties so you receive contact grill belts that perform as advertised every time.

- Customer focused service: Selling product is only the beginning. Taconic customer service is dedicated to long term support, from initial selection and installation through years of ongoing production. Our team is available to answer questions, troubleshoot and help optimize belt performance in your line.

Thanks to our engineering and quality teams, we are proud to offer some of the most advanced contact grilling belt materials on the market for industrial food processing.

Contact grill belt comparison

Use the table below to compare Taconic A1121, A1085 and A1060 PTFE coated fiberglass grill belt materials by thickness, weight, tensile and tear strength, dielectric strength and operating temperature range.

| Part Number | Overall Thickness (inches) | Coated Weight (lbs/sq yd) | Tensile Strength Warp/Fill (lbs/inch) | Tear Strength Warp/Fill (lbf) | Dielectric Strength (volts/mil) | Operating Temp (F°/C°) |

|---|---|---|---|---|---|---|

| A1121 | 0.013 | 1.26 | 375 / 290 | 25.0 / 13.0 | 150 | -100 / 500 |

| A1085 | 0.0145 | 1.46 | 350 / 290 | 11.0 / 11.5 | 200 | -100 / 500 |

| A1060 | 0.0122 | 1.22 | 310 / 200 | 10.5 / 9.5 | 200 | -100 / 500 |

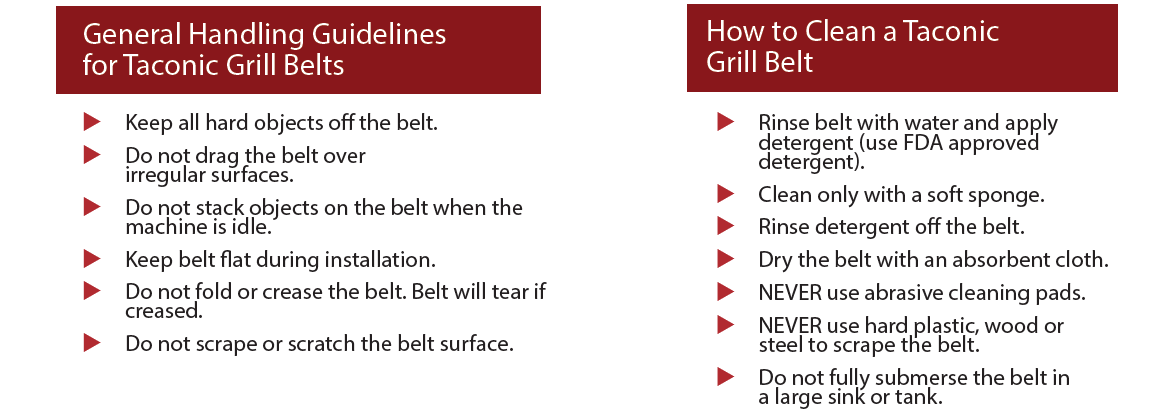

Use and care

Once you have your Taconic contact grill belt, it is important to understand how to correctly maintain them. Proper use and care help maximize belt life, maintain nonstick performance and support safe, consistent food production.

This information is also available in poster form, in a variety of languages, for employee reference and training in production areas.