TacSil F20BP Silicone Carrier Tape for SMT and Flexible PCB Assembly

Reusable High Temperature Silicone Carrier Solution for Precision Surface Mount Processing

TacSil F20BP Silicone Carrier Tape

TacSil F20BP is a high performance silicone carrier tape that offers a cost effective solution for FPC assembly compared to polyimide tapes, resin coated plates, and double sided tapes. These conventional methods can increase costs, reduce productivity, contaminate or damage flexible circuitry, limit print accuracy, and create environmental challenges. With TacSil F20BP, flexible circuit assembly becomes cleaner, faster, and easier.

TacSil F20BP carrier tape is available in sheet or roll form, giving process engineers and carrier designers flexibility in how they support SMT lines, LCD assemblies, and other advanced assembly operations.

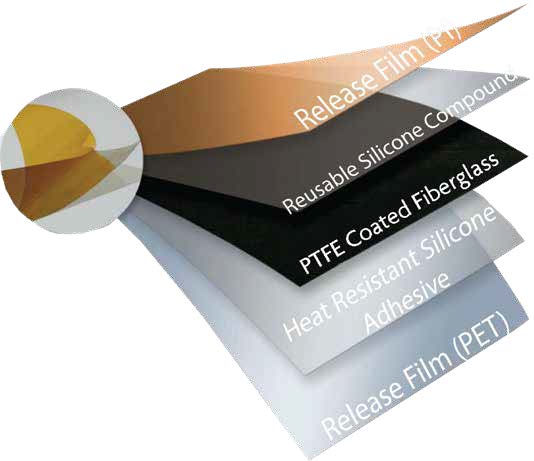

At a glance: TacSil F20BP combines a reusable silicone compound surface with a PTFE coated fiberglass base and PET release film to deliver stable, repeatable performance cycle after cycle.

Key Benefits of TacSil F20BP

Designed specifically for demanding surface mount processes, TacSil F20BP delivers long life, stable positioning, and clean release without adhesive residue.

- Performs more than 500 cycles in SMT processing

- Excellent dimensional stability at 500 °F

- Precise surface mounting with consistent tack

- No adhesive residue transferred to circuitry or carriers

- Superior surface flatness allows whole area fixation

- Excellent die cut properties for custom carrier designs

- Provides flexibility to carrier designers and process engineers

- Durable anti static surface for stable handling

Typical Applications

TacSil F20BP supports a wide range of high precision assembly and temporary fixing processes.

- SMT processing of flexible PCB assemblies

- SMT processing of thin rigid PCB assemblies

- Carrier for LCD assemblies

- Flip chip mounting processes

- Various temporary fixing and positioning applications

Process advantage: TacSil F20BP allows whole area fixation with a reusable silicone surface, which improves registration, supports high density placement, and helps protect delicate flexible circuitry.

Technical Data

| TacSil Grade | TacSil Thickness (mil) | 180 deg Peel Adhesion Active Side (oz/in) | 180 deg Peel Adhesion Mounting Side (oz/in) | Operating Temperature Max (°F) | Shelf Life |

|---|---|---|---|---|---|

| F20BP | 0.0050 | 1.0 ± 0.2 | 25 minimum | 500 | 12 months from D.O.M. |

Test methods: Thickness measured per ASTM D4969. Peel adhesion measured per ASTM D3330.

How to Apply TacSil F20BP in SMT Processing

For best performance, especially when using Durostone or aluminum carrier boards, proper pre aging and application practices are important. Other carrier materials do not require pre aging.

1. Pre age carrier boards when required

- Pre age Durostone or aluminum carriers at 500 °F for more than 3 minutes, or pass through the SMT reflow chamber for one cycle.

- For Durostone carriers, attach TacSil F20BP approximately two hours after pre aging.

- For aluminum carriers, attach TacSil F20BP before the aluminum cools below 100 °F.

2. Apply TacSil F20BP to the carrier

- Clean the surface of carrier boards with alcohol and allow to dry.

- Carefully remove the release liner from the adhesive side (clear liner).

- Attach the adhesive side of TacSil F20BP to the carrier board, avoiding trapped air.

- Carefully remove the release liner from the silicone side (amber PI film liner).

- Place the flexible PCB or assembly on the silicone surface for SMT processing.

Reusable performance: TacSil F20BP is designed for reuse. With proper handling, the same carrier can support many process cycles before replacement is required.

Cleaning and Maintenance

Proper cleaning helps maintain tack and extends the useful life of TacSil F20BP. Cleaning the active surface is recommended when tack is no longer high enough to hold the flexible circuitry.

- Remove surface contamination using a dedicated cleaning roller (recommended) or a soft cloth.

- Lightly moisten the cloth with Ethanol if needed.

- Do not use ketones such as Acetone, or solvents such as toluene and xylene for cleaning.

Cleaning rollers and refills are available in 80 mm x 20 m perforated adhesive sheet format.

Storage Recommendations

- Keep products away from direct UV exposure, oils, and other contaminants.

- Store in original packaging at 73 °F ± 4 °F and 50 ± 2 % RH.

- Avoid stacking heavy objects directly on TacSil rolls or sheets.

Taconic Expertise

Taconic was founded in 1961 by Lester T. Russell, the acknowledged inventor of the process for applying PTFE to fiberglass fabric. Today Taconic produces advanced engineered composite materials for diverse markets and is dedicated to quality, innovation, and environmental responsibility.

Our experienced R & D, engineering, and multilingual sales support teams collaborate closely with customers around the world to solve application challenges and optimize carrier designs for modern assembly processes.