Flooring and Carpet Manufacturing

a nonstick barrier between your machinery and the flooring components being created

Flooring and Carpet Manufacturing

PTFE coated fiberglass fabrics and belts for flooring and carpet manufacturing are a nonstick, chemical resistant, barrier between your machinery and the flooring or carpet components.

With exceptional release properties and easy to clean surfaces, Taconic’s PTFE coated materials increase your plant’s efficiency by minimizing prep, finish work, clean-up, and waste. The result – cost savings to you and a top-quality end-product your customers will love!

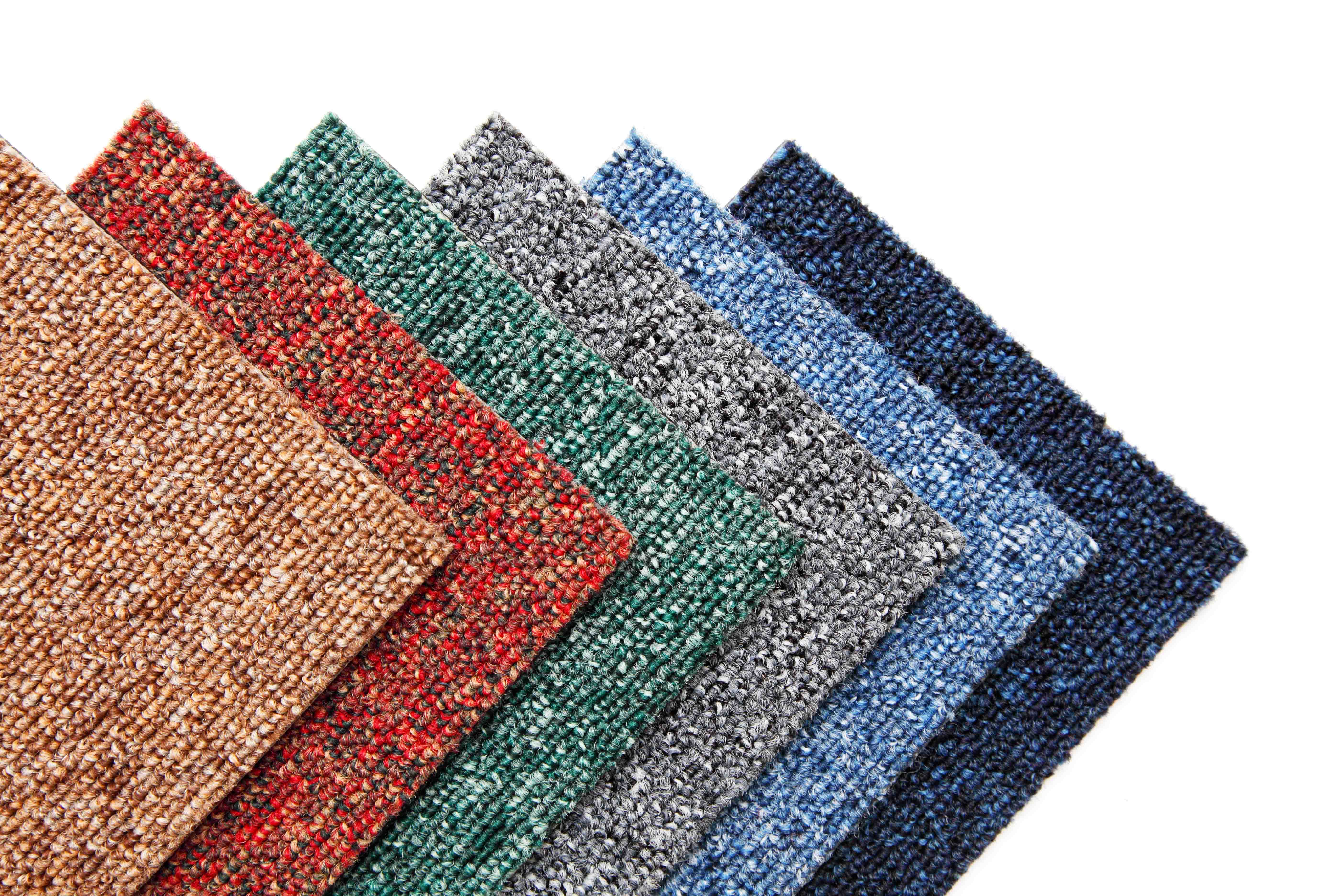

Whether you manufacture luxury vinyl plank, laminate flooring, rubber/walk-off mats, commercial carpet tile or even padded underlay, Taconic’s nonstick materials deliver the surface profile you need.

Benefits:

- Exceptional release properties up to 500 °F (260°C)

- Chemical resistant

- Easy to clean surface

- Reduces prep time, finish work, clean-up and waste

- Leads to a consistent finished product

Great for fabrication of:

- Vinyl plank flooring

- Laminate flooring

- Walk-off mats

- Rubber mats

- Anti-fatigue mats

- Commercial carpet tile

- Carpet underlay

Flooring and Carpet Manufacturing Product Data

| Product Number | Overall Thickness (inches) | Coated Weight (lbs/sq yd) | Tensile Strength Warp/Fill (lbs/inch) | Tear Strength Warp/Fill (lbf) | Dielectric Strength (volts/mil) |

|---|---|---|---|---|---|

| A1048 | 0.0245 | 2.15 | 600 / 575 | 40.00 / 40.00 |

150 |

| A1157 | 0.025 | 2.18 | 550 / 575 | 35.00 / 30.00 | 170 |

| 8274 | 0.0245 | 1.78 | 475 / 520 | 70.00 / 90.00 | 125 |

| 8278 | 0.0245 | 1.76 | 425 / 500 | 50.00 / 55.00 | 150 |

| 8279 | 0.025 | 1.98 | 410 / 600 | 25.00 / 20.00 | 200 |

The data herein are averages based on the authoritative testing of several lot numbers. This information is intended for comparison purposed only.