Solus® Architectural Fabric Features

Benefits of Solus® Architectural Fabric:

- Lightweight: Only a fraction of the weight of traditional building materials.

- High strength: Glass is one of the strongest textile fibers, having greater specific strength than steel wire of the same diameter.

- Flexible: Unlike most rigid building materials, the flexibility of Solus® products allows them to be tensioned into dynamic curvilinear shapes.

- Translucent: Allows for soft diffused lighting that evenly distributes light over interior or exterior surfaces.

- Low maintenance: Minimal cleaning is required over the life of the fabric. Due to its non-stick surface, rain washes dirt off the fabric surface while maintaining water repellence.

- Totally inert surface: The toughest environments such as fungus or acid rain will have no effect on the fabric surface.

- Weldable: Individual fabric panels are welded together to create large monolithic roof surfaces. The strength of the welded seams are stronger than the fabric itself.

- Long life: There is minimal degradation to the PTFE coated glass composite over its life. Today, Solus® Fabrics can be expected to perform for more that 25 years.

- Fire performance: Solus® Fabrics have achieved a Class A fire rating while still maintaining high translucency.

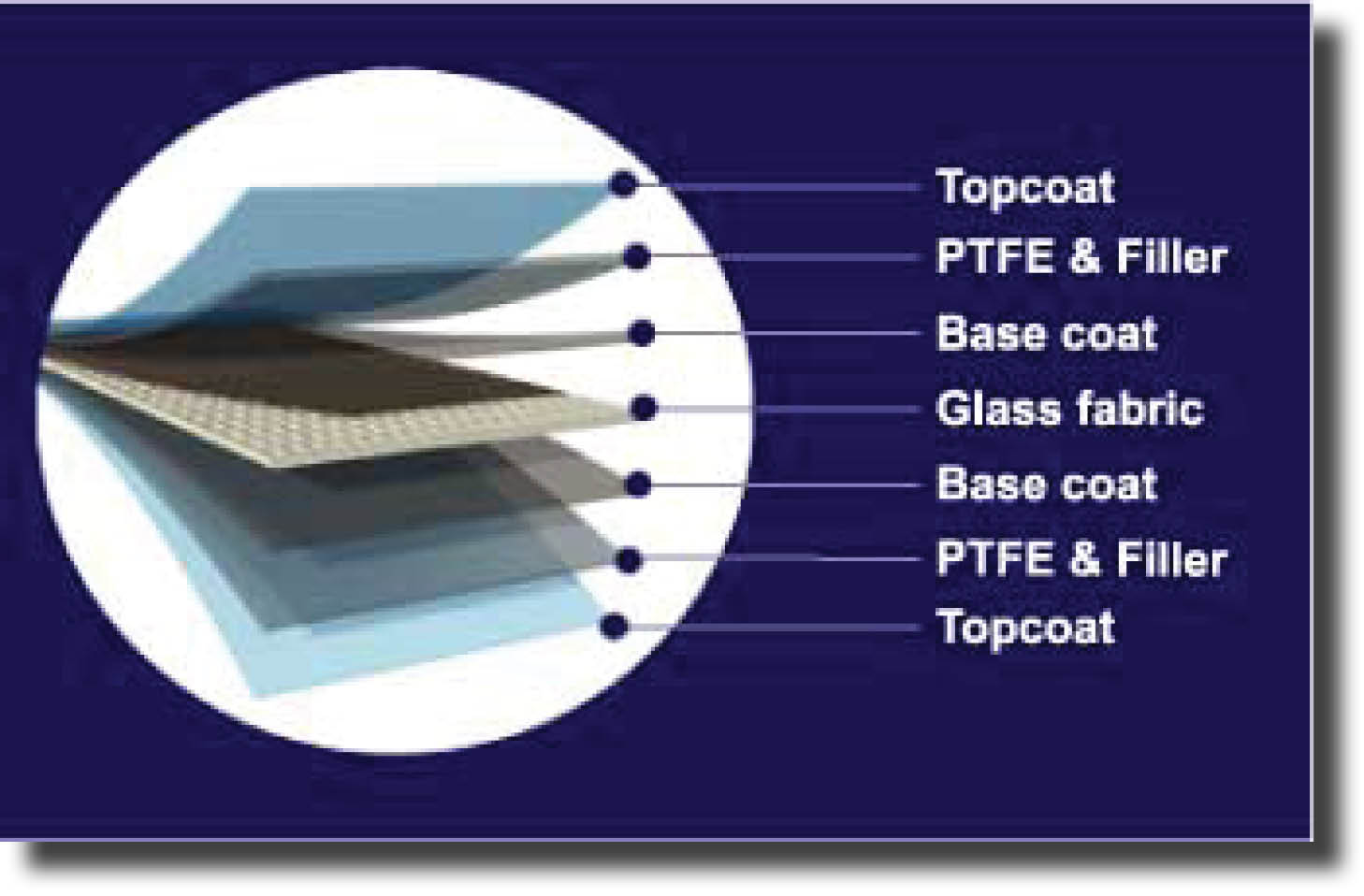

The multiple layers comprising Solus® Architectural Fabric offer unique properties:

Topcoat

The topcoat consists of an FEP layer to enhance impermeability, fungal resistance and weldability.

PTFE + Filler

Each PTFE+Filler layer consists of multiple built-up layers of PTFE dispersions. The PTFE has exceptional properties: resistance to most harsh chemicals, very low coefficient of friction, non stick properties, non flammability, excellent dielectric properties, resistance to aging, non toxic, UV resistant and moisture resistant properties. These layers of PTFE provide long term protection from all potential environmental degradation. Different types of fillers can be combined with the PTFE in order to obtain additional features like abrasion resistance, improved translucency or specific colors.

Base coat

The base coat is a critical part of the composite structure. It provides a solid anchoring to the glass fabric and is the base layer to the PTFE coat that will come on top. It also determines the flexibility characteristics of the finished coated product. Depending on the expected properties, different formulations can be used.

Glass fabric

The glass fabric is the “skeleton” of the composite and provides the mechanical properties of the finished coated product. Glass fabrics have very interesting characteristics:

- High Tensile Strength: Glass is one of the strongest textile fibers, having greater specific tensile strength than steel wire of the same diameter, at a lower weight.

- Dimensional Stability: Low elongation under load, generally 3% or less. Glass fibers produce fabrics with excellent dimensional stability under various types of conditions.

- High Heat Resistance: Glass fabrics have excellent heat resistance at relatively low cost. They retain approximately 50% of room temperature tensile strength at 700°F (371°C) and approximately 25% at 900°F (482°C) with a softening point of 1555°F (846°C) and a melting point of 2075° F (1121 °C).

- Fire Resistance: Composed of inorganic materials, glass fabrics are non combustible - a natural choice where flammability is a concern.

- Good Chemical Resistance: Like glass itself, glass fiber fabrics are highly resistant to attack by most chemicals.

- Durability: Being inert, glass fabrics are unaffected by sunlight, fungus or bacteria.

A particular type of glass filament is mainly used for the weaving of architectural fabrics used in big tensile structures. It is a continuous filament with a constant diameter of 3 micron. Only very few companies around the world are able to produce this type of filament at the level of quality requested by Taconic. This type of filament provides great flexibility and strength to the woven glass fabric. Depending on the application (inside or outside, decorative or structural fabric) and the stress factor applied to the fabric, many different weave patterns can be used.